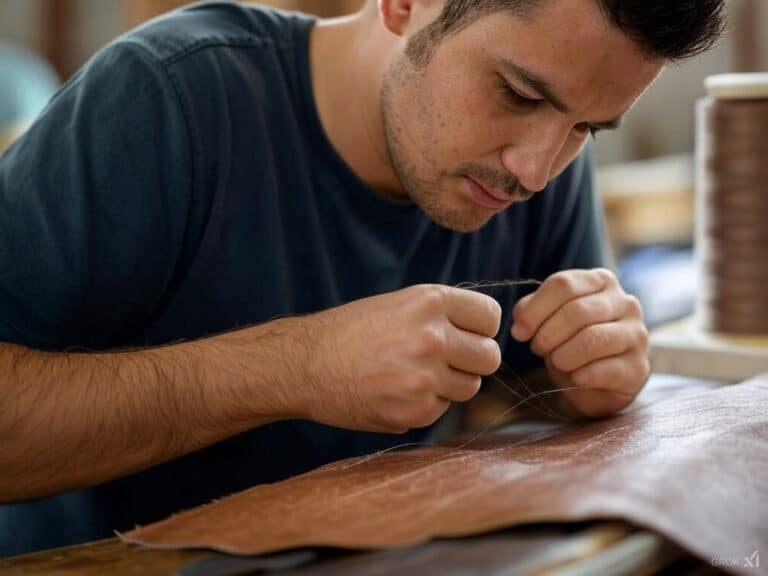

Last week, my buddy Dave sent me a text with a photo of his “epic leather belt fail”—a frayed stitch that snapped after two wears. “I used my mom’s quilting thread!” he said.

I winced. Leather isn’t fabric, and your thread can’t be an afterthought. Let’s talk about what works—so your next project doesn’t end up like Dave’s.

Why I Learned Leather Deserves Tougher Threads

Leather is dense and unforgiving—it requires a thread with high tensile strength. Unlike your everyday fabric, leather’s thick material needs a durable thread that won’t break under pressure. I once heard a cobbler say, “Sewing leather with cotton is like using dental floss to tow a truck.”

That image stuck with me. When working with leather, you need a thread that can stand up to the material. Weak threads lead to frayed seams and ruined projects, so investing in strong threads is a must.

Hanging by a Thread (@mistresstailor) shares a memorable sewing experience, proving that improvisation has its limits—especially when working with leather. The right tools and materials matter, and when it comes to stitching tough fabrics, using the proper thread can mean the difference between success and struggle.

The one and only time I chose to use them was for sewing a leather frock coat and I only had like 9 of them so I ended up using some nipple clamps too pic.twitter.com/3819xMi1h0

— Hanging by a Thread (@mistresstailor) December 7, 2023

My Go-To Heroes: Polyester vs. Nylon

When looking for the best sewing thread for leather, I quickly found that polyester and nylon are the heavyweights. Bonded nylon thread is my top pick for machine sewing—it’s UV-resistant and perfect for heavy-duty projects like horse saddles or knife sheaths.

A polyester thread is a bit more flexible and better for hand-sewing leather goods like watch straps or bags. Trust me on this: avoid linen thread since it weakens over time, and single-strand silk is just too fragile. Whether you choose bonded nylon or polyester depends on your project, but both far outperform any old cotton.

ImYourFuckleberry (@Fuckleberry90) swears by 500D or 1000D Cordura fabric, paired with T70 bonded nylon thread and a 110/18 needle—strong enough to sew through plywood. When working with tough materials like leather, the right thread and needle combo make all the difference in durability and performance.

I mostly use 500D or 1000D cordura fabric instead of canvas. T70 bonded nylon thread and 110/18 needle. It'll sew plywood so it'll handle any fabric I can find pic.twitter.com/7xdh8LncHd

— ImYourFuckleberry (@Fuckleberry90) February 16, 2023

When I Realized “Thicker Isn’t Always Better” (But Usually It Is)

Match your thread size to the leather thickness, for thicker leather-like belts or attaché cases, use 0.8–1.0mm thread. For thinner leather-like wallets or key fobs, use 0.4–0.6mm thread. I remember a leatherworker friend telling me, “Go one size up for high-stress areas like straps.”

It seems counterintuitive, but using the right thread size ensures your seams are both strong and flexible without adding bulk. The goal is a strong thread that complements the leather’s natural toughness.

How I Discovered Waxed Threads: The Secret Weapon in My Toolbox

Ever tried hand-sewing leather and ended up with burned fingers or chapped threads? That’s where waxed threads come in. Waxed threads reduce friction and make the sewing process smoother and more comfortable.

My colleague Sarah once told me, “Using bonded nylon with beeswax is like stitching with butter—it just flows perfectly.” This simple trick not only improves the quality of your stitch but also protects your hands, so waxed threads are a secret weapon you should have in your toolbox.

Quick Cheat Sheet: Threads by Project

Belts/Saddles: Use bonded nylon thread, thick (around 1.0mm).

Wallets/Keychains: Use polyester thread, smallest size (around 0.4mm).

Machine Sewing: Always use bonded thread to avoid unraveling.

Weaver Leather Supply (@leathersupplies) shares expert insights on hand-sewing leather, from the differences between waxed and machine thread to techniques for diamond- and flat-chiseled leather. Mastering these details can make all the difference in durability and craftsmanship—because the right thread and technique matter as much as the leather itself.

Chuck demonstrates a few more of his favorite leather hand-sewing tips and tricks, from comparing waxed thread to machine thread to looking at hand-sewing methods for diamond-chiseled leather versus flat-chiseled. What's your favorite hand-sewing trick?https://t.co/oYgIpSegFj pic.twitter.com/buj48IPqmu

— Weaver Leather Supply (@leathersupplies) August 18, 2023

Don’t Mess Up: Why the Right Needle Matters, Too

Even the best thread won’t save your project if you use the wrong needle. For thick leather, wedge point needles are a must; they cut through the material without causing damage. For detailed work or precision stitching on delicate areas, John James needles are the way to go.

I once heard a pro tell a horror story: “I ruined a custom briefcase using the wrong needle size—it looked like a raccoon attacked it.” This experience taught me that matching your needle to your thread and material is just as important as choosing the right thread.

The One Mistake I Made (And You Should Avoid It)

One mistake—and one I’ve made myself—is forgetting the bobbin thread test. Always test your thread tension on a scrap of leather before you start your project.

If your stitches pucker or your seam doesn’t lie flat, switch to braided thread—it’s more forgiving and can adjust to minor tension issues. Take a few extra minutes to test your setup and save yourself the headache later.

Next time you’re sewing leather, be a pro: use bonded nylon or polyester, match the thread size to your leather, and don’t let the wrong needle screw you up. Even Dave got it right on his third try—you can, too.